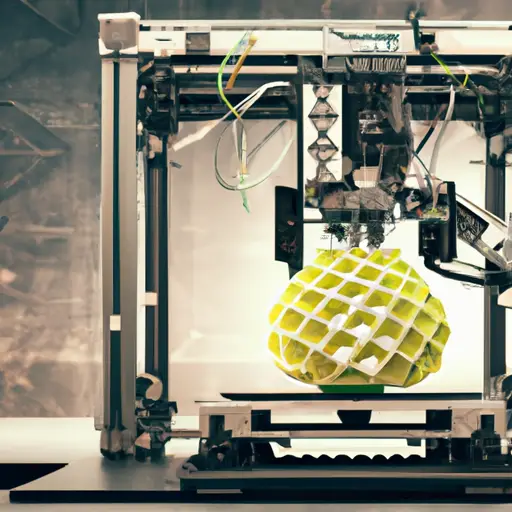

In the world of 3D printing, software serves as the master architect, orchestrating the intricate dance of design, simulation, and production. Like a conductor leading a symphony, software harmonizes the complex elements necessary for transforming digital models into physical reality.

From CAD software that shapes the initial blueprint to slicing software that prepares the design for printing, each step relies on the precision and ingenuity of software tools.

This article delves into the pivotal role software plays in revolutionizing the 3D printing landscape.

Designing and Modeling Software

One of the most essential tools for creating 3D printable models is the use of specialized designing and modeling software. These software programs are specifically designed to assist users in creating intricate and complex 3D models that can be easily printed using a 3D printer. They provide a wide range of features and tools that enable users to manipulate and refine their designs, ensuring that the final product meets their exact specifications.

To effectively utilize these software programs, it is important to understand various 3D modeling techniques. These techniques involve creating a virtual representation of an object using digital tools and techniques. This includes techniques such as polygonal modeling, NURBS modeling, and sculpting, among others. Each technique has its own advantages and limitations, and the choice of technique depends on the specific requirements of the design.

In addition to understanding 3D modeling techniques, it is also important to consider the software requirements for creating 3D printable models. These include the hardware requirements of the computer system, such as processing power and memory, as well as the software compatibility with the 3D printer being used. It is crucial to ensure that the chosen software is compatible with the printer’s file formats and can generate the necessary instructions for the printer to create the desired object.

CAD Software for 3D Printing

When it comes to CAD software for 3D printing, there are several key points to consider.

Firstly, these software tools allow designers to create intricate 3D models with precision and detail.

Secondly, CAD software plays a crucial role in optimizing printing parameters, ensuring that the final print is of high quality and accuracy.

Lastly, these tools help to ensure print compatibility by generating files that can be easily interpreted by 3D printers.

Designing Intricate 3D Models

CAD software plays a crucial role in the creation of complex and detailed 3D models for 3D printing. With the advancement of additive manufacturing and the availability of advanced materials, designers are now able to push the boundaries of what can be created using CAD software. These software tools provide designers with the ability to design intricate models with precision, allowing for the creation of complex geometries and intricate details. CAD software also enables designers to optimize the design for 3D printing, ensuring that the final printed object is structurally sound and functional. By using CAD software, designers can explore new design possibilities and unleash their creativity, leading to the creation of innovative and unique 3D printed objects.

| 1. | Advanced materials | CAD software enables designers to take advantage of advanced materials in their 3D models, allowing for the creation of objects with unique properties and characteristics. |

| 2. | Additive manufacturing | CAD software is essential for additive manufacturing, as it enables designers to create precise and complex models that can be printed layer by layer. |

| 3. | Precision and optimization | CAD software provides designers with the tools to design with precision and optimize their models for 3D printing, ensuring the final printed object meets the desired specifications. |

Optimizing Printing Parameters

Two key factors in achieving high-quality 3D prints are optimizing printing parameters and utilizing CAD software to ensure precise and accurate results.

To optimize printing parameters, it is important to consider the following:

-

Layer height: Adjusting the layer height can significantly impact print quality. A smaller layer height allows for finer details but increases print time.

-

Print speed: Balancing print speed is crucial to prevent issues such as under-extrusion or warping. Slower speeds generally result in better print quality.

-

Temperature settings: Accurate temperature control is essential for material selection. Different materials require specific temperatures to achieve optimal print quality.

-

Support structures: Properly configuring support structures is necessary to ensure the integrity of the print, especially for complex designs.

Ensuring Print Compatibility

To ensure print compatibility in 3D printing, it is crucial to utilize the appropriate CAD software that supports the desired file formats and provides the necessary tools for accurate and seamless printing.

CAD software plays a vital role in translating design concepts into printable models by converting them into the required file formats such as STL or OBJ.

Additionally, CAD software offers various tools for print quality optimization, allowing users to adjust parameters such as layer thickness, infill density, and support structures, to achieve the desired level of detail and strength in the printed object.

Furthermore, CAD software enables material compatibility testing, allowing users to simulate and validate the printing process for specific materials, ensuring successful printing without material waste or damage to the printer.

Simulation and Optimization Tools

Simulation and optimization tools play a crucial role in enhancing the efficiency and accuracy of 3D printing processes. These tools enable manufacturers to analyze the feasibility of a design and make necessary adjustments before printing. One key aspect of simulation analysis is evaluating material compatibility. By simulating the printing process, manufacturers can identify potential issues such as warping, shrinkage, or deformation that may arise due to the specific material being used. This allows them to choose the most suitable material for their intended application and optimize the printing parameters accordingly.

Here are some key features and benefits of simulation and optimization tools in 3D printing:

- Design validation: Simulation tools enable manufacturers to validate their designs and ensure that they can be successfully printed without any defects or errors.

- Optimized printing parameters: By simulating the printing process, manufacturers can optimize parameters such as print speed, temperature, and support structures, leading to improved print quality and reduced print time.

- Cost and time savings: Simulation tools help identify potential issues early in the design phase, reducing the need for costly and time-consuming iterations during the actual printing process.

- Process predictability: By simulating the printing process, manufacturers can gain a better understanding of how different design modifications or material choices may affect the final product, allowing for more predictable and reliable outcomes.

Slicing Software for Print Preparation

Slicing software plays a crucial role in 3D printing by converting 3D models into printable instructions that the printer can understand.

One important aspect of slicing is the technique used to slice the model, which determines the accuracy and quality of the printed object.

Additionally, it is important to consider the compatibility of the slicing software with the specific printer being used to ensure seamless communication and optimal printing results.

Slicing Techniques for Accuracy

Importantly, selecting the appropriate slicing software greatly contributes to the accuracy of 3D printing. Slicing techniques for accuracy play a crucial role in achieving high-quality prints. Here are some important techniques to consider:

-

Layer height optimization: Adjusting the layer height can significantly impact the accuracy of the printed object. Finer layer heights result in smoother surfaces and higher accuracy, but printing time increases.

-

Infill density control: Optimizing the infill density helps balance strength and material usage. Higher infill density enhances structural integrity but may increase printing time.

-

Support structures generation: Slicing software generates support structures to ensure overhangs and complex geometries are properly printed. Proper support structure placement and removal techniques are essential for achieving accurate prints.

-

Print speed adjustment: Fine-tuning the print speed based on the complexity of the object can improve accuracy. Slower speeds allow for more precise movements and reduce the chances of errors.

Software Compatibility With Printers

Users must ensure that their chosen slicing software is compatible with their printers, as this will greatly impact the print preparation process. Slicing software plays a crucial role in converting 3D models into printable instructions, known as G-code, which the printer understands. Software development and printer firmware are constantly evolving, making compatibility an important consideration.

To illustrate the compatibility between slicing software and printers, the following table provides an overview of popular slicing software and their compatibility with different printer brands:

| Slicing Software | Printer Compatibility |

|---|---|

| PrusaSlicer | Prusa i3, Ultimaker |

| Cura | Creality, Lulzbot |

| Simplify3D | MakerBot, Flashforge |

| Slic3r | Original Prusa, Anet |

It is essential for users to research and select a slicing software that aligns with their printer brand and model. This ensures a seamless and efficient print preparation process, resulting in high-quality 3D prints.

Control Software for Printer Operation

The efficiency of a 3D printer’s operation heavily relies on the control software implemented. Control software is responsible for managing and coordinating all aspects of the printing process, from file preparation to the actual printing. It plays a crucial role in ensuring accurate and reliable prints.

Here are some key aspects of control software for printer operation:

-

Printer Calibration: Control software enables users to calibrate their printers, ensuring that the machine is properly aligned and capable of producing accurate prints. This calibration process involves adjusting various parameters such as nozzle height, bed leveling, and extrusion rate.

-

File Slicing: Control software slices the 3D model into layers and generates the instructions required for the printer to build the object layer by layer. It determines the toolpath, speed, temperature, and other parameters necessary for successful printing.

-

Real-time Monitoring: Control software provides real-time monitoring of the printing process, displaying crucial information such as print progress, temperature, and any potential errors or warnings. This allows users to intervene if necessary and maintain control over the printing process.

-

Firmware Updates: Control software also facilitates firmware updates for the printer. Firmware updates often include bug fixes, performance improvements, and new features, ensuring that the printer operates at its best.

Post-Processing and Finishing Software

After the 3D printing process is completed, post-processing and finishing software can be used to further enhance the quality and appearance of the printed object.

Post-processing automation refers to the use of software tools that automate the post-printing tasks, such as removing support structures, cleaning the object, or applying a protective coating. This automation can significantly improve the efficiency and consistency of the post-processing workflow.

One important aspect of post-processing software is the inclusion of surface smoothing algorithms. These algorithms analyze the geometry of the printed object and apply smoothing techniques to reduce the appearance of layer lines and other surface imperfections. By automatically adjusting the geometry, these algorithms can create a smoother and more refined surface finish.

Additionally, post-processing and finishing software can also enable the user to add intricate details or decorations to the printed object. This can be achieved through the use of texture mapping or embossing features provided by the software. By leveraging these tools, users can personalize their creations and add a unique touch to their 3D printed objects.

Future Trends in 3D Printing Software

One major trend in the future of 3D printing software is the increasing integration of artificial intelligence and machine learning algorithms to enhance the design and printing process. This trend is driven by the need for more efficient and automated workflows in 3D printing.

Here are some key developments to watch out for:

-

Smart Design Assistance: Artificial intelligence algorithms can analyze design requirements and provide suggestions for optimizing designs, ensuring that they are structurally sound and printable. This helps users save time and effort in the design phase.

-

Real-Time Monitoring and Quality Control: AI-powered software can monitor the printing process in real-time, detecting potential defects or errors and making adjustments on the fly. This improves the overall print quality and reduces the risk of failed prints.

-

Cloud-Based Collaboration: Cloud-based 3D printing software solutions enable seamless collaboration between designers, engineers, and manufacturers. These solutions allow for easy file sharing, version control, and remote access to printers, making it easier to work together on complex projects.

-

Predictive Maintenance: By analyzing data from sensors and historical printer performance, AI algorithms can predict when a printer is likely to require maintenance or encounter issues. This proactive approach helps minimize downtime and ensures optimal printer performance.

These advancements in artificial intelligence and machine learning are shaping the future of 3D printing software, making the process more efficient, reliable, and accessible.

Frequently Asked Questions

How Does Designing and Modeling Software Contribute to the Overall 3D Printing Process?

Designing and modeling software plays a crucial role in the overall 3D printing process. It enables users to create intricate 3D models, apply various 3D modeling techniques, and ensures accuracy and precision. Additionally, regular software updates are important to enhance functionality and introduce new features.

What Are the Key Features to Look for When Selecting CAD Software for 3D Printing?

When selecting CAD software for 3D printing, key considerations include ease of use, compatibility with your printer, support for various file formats, advanced modeling capabilities, and efficient slicing algorithms. A thorough comparison of options is crucial for optimal results.

How Do Simulation and Optimization Tools Enhance the Efficiency and Quality of 3D Printed Objects?

Simulation tools and optimization tools play a crucial role in enhancing the efficiency and quality of 3D printed objects. By simulating and optimizing the printing process, these tools can identify potential issues and optimize parameters, resulting in improved outcomes.

What Is the Role of Slicing Software in the Preparation of 3D Prints?

Slicing software plays a crucial role in preparing 3D prints by converting a digital model into a series of instructions for the printer. It ensures accurate layering, proper support structures, and optimizes printing parameters. File formats are also important for compatibility and preserving design integrity.

How Does Control Software for Printer Operation Ensure Smooth and Accurate Printing?

Control software for printer operation ensures smooth and accurate printing by providing real-time monitoring of the printing process. It also ensures material compatibility, allowing users to select the appropriate settings and optimize the printing parameters for the desired outcome.

Conclusion

In conclusion, software plays a crucial role in the world of 3D printing.

From designing and modeling to simulation and optimization, software tools enable users to create, prepare, and operate the printing process.

Slicing software ensures print accuracy, while post-processing and finishing software add the final touches to the printed object.

As technology advances, we can expect future trends in 3D printing software to further enhance the efficiency and capabilities of this revolutionary manufacturing technique.