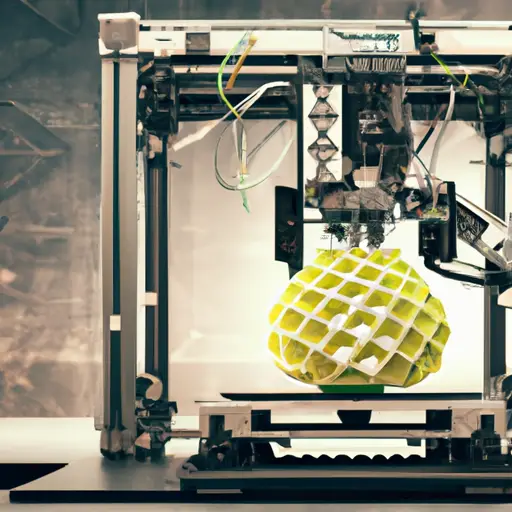

In the realm of three-dimensional printing, the journey to perfection is often paved with obstacles. Like the intricate layers that compose a printed object, the challenges faced by enthusiasts and professionals alike require meticulous attention and problem-solving skills.

This article serves as a guiding light, shedding insight on the most common hurdles encountered during the 3D printing process. From troubleshooting print quality issues to optimizing bed adhesion, we delve into the technical intricacies and offer analytical solutions to empower you in overcoming these common 3D printing challenges.

Troubleshooting Print Quality Issues

One of the most important steps in troubleshooting print quality issues is identifying the source of the problem through thorough examination and analysis. When it comes to 3D printing, there are several common challenges that can affect the quality of the prints. Two such challenges are improving print speed and troubleshooting layer shifting.

Print speed is a critical factor in 3D printing, as it directly affects the time it takes to complete a print. However, increasing the print speed can sometimes lead to compromised print quality. This can result in a decrease in the overall accuracy and resolution of the printed object. To improve print speed without compromising quality, it is important to optimize the printer settings, such as layer height, print temperature, and infill density. Additionally, using high-quality filaments and ensuring proper bed adhesion can also contribute to faster and better prints.

Layer shifting is another common issue that can negatively impact print quality. This occurs when the layers of a print shift horizontally, causing misalignment and distortion. Layer shifting can be caused by various factors, including mechanical issues, loose belts, or even insufficient power supply. To troubleshoot layer shifting, it is essential to carefully inspect the printer’s mechanical components, such as the belts, pulleys, and motor. Ensuring that all components are properly tightened and aligned can help minimize layer shifting and improve print quality.

Dealing With Filament Jams and Clogs

To effectively address filament jams and clogs in 3D printing, it is crucial to understand the causes and implement proper preventive measures. Filament jams occur when the filament gets stuck in the nozzle, preventing smooth extrusion. Clogs, on the other hand, happen when the filament solidifies inside the nozzle, obstructing the filament flow. These issues can lead to failed prints and wasted material, causing frustration and delays in the printing process.

To prevent nozzle blockages and troubleshoot extrusion problems, it is important to follow these preventive measures:

| Preventive Measures | Description | Benefits |

|---|---|---|

| Regular Nozzle Cleaning | Periodically clean the nozzle to remove any residue or debris. | Ensures smooth filament flow and reduces the likelihood of clogs. |

| Filament Quality | Use high-quality filament that is less likely to contain impurities or inconsistencies. | Minimizes the risk of filament jams and improves print quality. |

| Proper Filament Storage | Store filament in airtight containers with desiccants to prevent moisture absorption. | Reduces the chances of filament becoming brittle and causing clogs. |

| Adjusting Print Settings | Optimize print settings such as temperature, retraction, and print speed for better extrusion. | Helps prevent filament jams and clogs by ensuring proper melting and flow. |

Optimizing Bed Adhesion for Successful Prints

Achieving optimal bed adhesion is essential for ensuring successful 3D prints. Without proper bed adhesion, prints can fail, warp, or detach from the print bed, resulting in wasted time, filament, and effort.

To optimize bed adhesion, consider the following techniques:

-

Leveling the bed: Ensuring the print bed is perfectly leveled is crucial. This ensures that the nozzle is at the correct distance from the bed, allowing for proper filament deposition and adhesion.

-

Using a suitable printing surface: Choosing the right printing surface can greatly improve bed adhesion. Options such as glass, PEI sheets, or adhesive materials like painter’s tape or glue sticks can provide a better grip for the printed object.

-

Applying adhesion aids: In some cases, additional adhesion aids may be necessary to improve bed adhesion. These can include using a brim or raft, which provide extra surface area for the print to adhere to, or applying a specialized adhesive like hairspray or a 3D printing adhesive spray.

Calibrating Your 3D Printer for Accurate Results

When calibrating your 3D printer, it is crucial to ensure accurate results for precise and high-quality prints. Fine-tuning extrusion settings and adjusting print speed are two important aspects of calibration that can significantly impact the final output.

To achieve accurate results, it is important to calibrate the extrusion settings of your 3D printer. This involves adjusting the flow rate and extruder steps per millimeter (E-steps) to ensure the correct amount of filament is being extruded. Fine-tuning these settings can help eliminate issues such as under-extrusion or over-extrusion, resulting in more accurate and consistent prints.

Another factor to consider when calibrating your printer is the print speed. Adjusting the print speed can help optimize the overall print quality and reduce the risk of print failures. It is important to find the right balance between speed and quality, as printing too fast can lead to poor layer adhesion and loss of detail, while printing too slow can result in longer print times.

To give you a better understanding, here is a table summarizing the key aspects of calibrating your 3D printer for accurate results:

| Aspects of Calibration | Description |

|---|---|

| Fine-tuning extrusion settings | Adjusting flow rate and E-steps to ensure accurate filament extrusion. |

| Adjusting print speed | Finding the right balance between speed and quality to optimize print quality and reduce the risk of print failures. |

Exploring Post-Processing Techniques for Finishing Touches

One common challenge in 3D printing is achieving the desired surface finish, and exploring post-processing techniques can help address this issue. After a 3D print is completed, there are various methods available to enhance the surface smoothness and achieve a more polished final product.

Here are three post-processing techniques that can be employed to improve the surface finish of 3D printed objects:

-

Sanding and Polishing: Sanding is a common technique used to remove layer lines and rough surfaces. Starting with a coarse grit sandpaper and gradually moving to finer grits helps in achieving a smooth finish. Polishing compounds and tools can further enhance the shine and remove any remaining imperfections.

-

Applying Paint and Coatings: Painting is an effective way to add color and protect the surface of a 3D printed object. Primers are often used as a base to ensure good adhesion, followed by applying the desired paint or coating. This step not only improves aesthetics but also provides an additional layer of protection.

-

Using Chemical Treatments: Chemical treatments such as acetone vapor smoothing can be employed to smooth the surface of 3D printed objects made from ABS plastic. The vapor causes the outer layers of the plastic to melt, resulting in a smoother and more polished appearance.

Frequently Asked Questions

What Are Some Common Troubleshooting Steps for Addressing Print Quality Issues in 3D Printing?

To address print quality issues in 3D printing, troubleshooting steps involve adjusting the nozzle height, ensuring proper filament flow, optimizing temperature settings, and calibrating the bed level. These measures contribute to achieving higher print quality and resolving common challenges.

How Can I Resolve Filament Jams and Clogs in My 3D Printer?

Troubleshooting filament jams and preventing filament clogs are essential for maintaining optimum performance in 3D printers. By following proper cleaning procedures, adjusting temperature settings, and ensuring proper filament feeding, these issues can be effectively resolved.

What Are Some Effective Techniques for Optimizing Bed Adhesion to Ensure Successful Prints?

Optimizing nozzle temperature and using adhesion aids are effective techniques for ensuring successful 3D prints. These methods improve bed adhesion, preventing print failures and ensuring the quality of the final product.

How Can I Calibrate My 3D Printer to Achieve Accurate Results?

To achieve accurate results when using a 3D printer, it is essential to calibrate the nozzle temperature and adjust the print speed. These factors play a crucial role in ensuring precise and high-quality prints.

What Are Some Post-Processing Techniques That Can Be Used to Enhance the Final Appearance of 3D Printed Objects?

Post-processing techniques are essential for enhancing the final appearance of 3D printed objects. Surface finishing methods, such as sanding, polishing, and painting, can be used to achieve a smooth and aesthetically pleasing finish, transforming raw prints into professional-quality objects.

Conclusion

In conclusion, by addressing common challenges in 3D printing, such as print quality issues, filament jams and clogs, bed adhesion, printer calibration, and post-processing techniques, users can achieve more accurate and successful results.

By employing technical and precise approaches, individuals can overcome these obstacles and create high-quality 3D prints. It is crucial to maintain a detailed understanding of troubleshooting techniques and employ the necessary adjustments to achieve optimal outcomes.