In the ever-evolving landscape of manufacturing, one technology has steadily gained traction and transformed the way products are created – 3D printing.

This cutting-edge method has revolutionized various industries by enabling faster prototyping, customization, and reduced waste.

However, understanding the cost dynamics of 3D printing is crucial for decision-makers.

By delving into the intricacies of material costs, machine expenses, labor, and training, as well as post-processing and finishing, organizations can strategically evaluate the return on investment (ROI) of this transformative technology.

Cost of Materials

How do the costs of materials impact the overall expenses of 3D printing?

Material selection and cost optimization play a crucial role in determining the overall expenses associated with 3D printing. The choice of materials significantly affects the quality and functionality of the printed objects, as well as the cost of production. Different materials have varying costs, with some being more expensive than others. Therefore, it is essential to carefully select the materials that align with the specific requirements of the printed object while considering the budget constraints.

Cost optimization in material selection involves finding the right balance between cost and quality. By analyzing the properties and characteristics of various materials, manufacturers can identify the most cost-effective options that meet the desired specifications.

Furthermore, recycling and waste management in 3D printing can also contribute to cost reduction. By recycling unused or failed prints, manufacturers can minimize material waste and reduce expenses associated with material procurement.

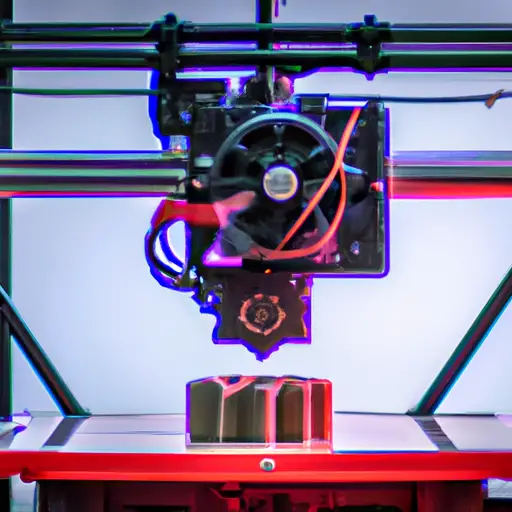

Machine Acquisition and Maintenance Expenses

Effectively managing machine acquisition and maintenance expenses is crucial in ensuring the long-term cost efficiency and operational effectiveness of 3D printing processes. These expenses can significantly impact the overall cost of running a 3D printing operation.

Here are some key factors to consider:

-

Machine Reliability: Investing in reliable 3D printers is essential to minimize maintenance and repair costs. High-quality machines are less likely to break down frequently, reducing downtime and associated expenses.

-

Software Licensing Costs: 3D printers require software to operate, and these software licenses can come with a price tag. It is important to factor in the cost of software licenses when budgeting for machine acquisition and maintenance.

-

Regular Maintenance: Regular maintenance is necessary to keep the machines in optimal condition. This includes cleaning, calibrating, and replacing worn-out parts. Proper maintenance helps prevent costly breakdowns and extends the lifespan of the machines.

-

Training and Support: Investing in training and support for machine operators can help maximize machine performance and reduce the risk of errors. Well-trained operators can identify and address minor issues before they escalate into major problems.

Labor and Training Costs

One of the key considerations in the cost dynamics of 3D printing is the allocation of adequate resources towards labor and training expenses. Skill development and employee productivity play crucial roles in maximizing the benefits of 3D printing technology. Investing in training programs ensures that employees have the necessary skills and knowledge to operate and maintain the 3D printers effectively, leading to increased productivity and reduced errors.

Table: Labor and Training Costs

| Aspects | Description | Importance |

|---|---|---|

| Skill development | Investing in training programs for employees to operate 3D printers | Enhances employee expertise and efficiency |

| Employee productivity | Ensuring employees are equipped with necessary skills and knowledge | Maximizes output and reduces operational costs |

By providing employees with the opportunity to enhance their skill sets through training, companies can improve overall efficiency and output quality. Skilled operators can also troubleshoot and solve technical issues independently, reducing the need for external assistance and minimizing downtime. Moreover, well-trained employees are more likely to adopt best practices, leading to higher production yields and fewer errors.

Post-Processing and Finishing Expenses

Managing post-processing and finishing expenses is a critical aspect to consider in the cost dynamics of 3D printing. After the printing process is complete, additional steps are often required to achieve the desired surface finish and quality. These post-processing and finishing expenses can significantly impact the overall cost of a 3D printed part.

Here are some key factors to consider:

-

Surface treatment options: Depending on the desired outcome, various surface treatment options are available. These include sanding, polishing, painting, or applying coatings. Each option has its own associated costs, which should be factored into the overall budget.

-

Outsourcing options: Some companies choose to outsource post-processing and finishing tasks to specialized service providers. This can be a cost-effective solution, especially for smaller businesses that may not have the necessary equipment or expertise in-house. However, it is important to carefully consider the costs and quality of outsourcing options.

-

Time and labor: Post-processing and finishing tasks require additional time and labor, which should be accounted for in the cost analysis. The complexity of the part, the desired finish, and the skill level of the operators can all influence the time and labor costs associated with post-processing.

-

Quality control: Ensuring the quality of the finished part is essential. This may involve additional inspections, testing, or certifications, which can add to the overall expenses.

Evaluating the Return on Investment (ROI)

Significantly, evaluating the Return on Investment (ROI) is a crucial step in determining the financial viability of implementing 3D printing technology. To assess the potential returns, companies must consider the advantages of outsourcing and the long-term sustainability of 3D printing.

Outsourcing certain aspects of the 3D printing process can provide cost savings and increase ROI. By partnering with external service providers, companies can reduce the need for expensive machinery and skilled labor, allowing them to focus on their core competencies. Additionally, outsourcing can provide access to specialized expertise and advanced technologies, enhancing the overall quality and efficiency of the printing process.

Furthermore, evaluating the long-term sustainability of 3D printing is essential for ROI analysis. While initial costs may be higher compared to traditional manufacturing methods, 3D printing offers numerous advantages in terms of material usage, waste reduction, and supply chain optimization. These factors contribute to a more sustainable and environmentally friendly production process, which can translate into long-term cost savings and increased profitability.

To illustrate the potential ROI of 3D printing, consider the following table:

| Cost Factor | Traditional Manufacturing | 3D Printing |

|---|---|---|

| Equipment | High | Moderate |

| Labor | Moderate | Low |

| Material Usage | Moderate | Low |

| Sustainability | Low | High |

Frequently Asked Questions

What Are the Environmental Impacts of 3D Printing and How Does It Affect the Cost Dynamics?

The environmental impacts of 3D printing can affect the cost dynamics. By considering factors such as material usage, energy consumption, and waste generation, businesses can analyze the sustainability and financial implications of adopting 3D printing technology.

Are There Any Legal Considerations or Regulations That Businesses Need to Be Aware of When Using 3D Printing Technology?

Legal considerations and regulatory compliance are critical for businesses using 3D printing technology. Understanding the legal landscape, such as intellectual property rights and product liability, can help mitigate potential risks and ensure compliance with applicable laws and regulations.

How Does the Complexity or Design Intricacy of a 3D Printed Object Affect Its Production Cost?

The complexity or design intricacy of a 3D printed object can significantly impact its production cost. As the design becomes more intricate, it requires more time, materials, and expertise, leading to increased production costs.

Are There Any Hidden Costs Associated With 3D Printing That Businesses Should Be Aware Of?

Hidden costs associated with 3D printing can impact businesses. These costs may include maintenance expenses, which can arise from the need to repair or replace components, resulting in additional financial burdens beyond the initial investment.

Can 3D Printing Help in Reducing Overall Production Costs in the Long Run, and if So, How?

Yes, 3D printing has the potential to reduce manufacturing costs and provide long-term cost savings. By eliminating the need for traditional manufacturing processes and reducing material waste, businesses can achieve greater efficiency and lower production costs over time.

Conclusion

In conclusion, the cost dynamics of 3D printing involve various factors such as material expenses, machine acquisition and maintenance costs, labor and training expenses, and post-processing and finishing expenditures.

Evaluating the return on investment (ROI) is crucial to determine the financial feasibility of adopting 3D printing technology.

It is interesting to note that according to a recent study, companies that implemented 3D printing experienced an average cost reduction of 40% in their manufacturing processes.

This statistic highlights the potential cost-saving benefits of 3D printing for businesses.